For decades we must deal with a significantly decreasing air quality caused by industrialization, wildfires, higher temperatures leading to an increase in harmful air pollutants. For this reason, there is a strong trend toward higher performance filter systems. When COVID-19 surfaced, it accelerated this trend and gave global visibility to the importance of improved indoor air quality in both residential and commercial applications.

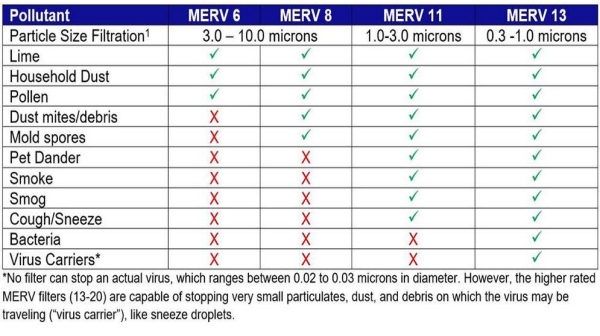

MERV filter ratings

In North America, filters are rated by MERV – Minimum Efficiency Reporting Value – with higher numbers indicating better performance in removing particulates/contaminants (an analogous system exists in Europe under ISO standards). A typical residential filter resides in the MERV 8 performance range, while most hospitals utilize filters in the MERV 14 or higher range – oftentimes, using multiple filters in sequence to achieve the high level of filtration required for hospital applications.

The table below demonstrates how higher rated MERV filters are able to filter more contaminants out of the air, with MERV 13 to MERV 20 filtering all the way down to the level of a virus carrier (debris that ranges from 0.3 microns to 1.0 micron in diameter).

Increasing filtration requirements

As the pandemic progressed, we saw a further focus on higher efficiency media and increased ventilation across all applications. The CDC and ASHRAE provide general guidance for the use of higher-efficiency filter media where possible – recommending at least MERV 13 to combat SARS-CoV-2, the virus that causes COVID-19.

With the onset of COVID-19, these higher rated filters have become an area of focus for many building and HVAC system designers who are looking for solutions that could potentially help slow or stop the spread of the virus between rooms. While historically, these types of filters have been required only in hospitals, we are now seeing emphasis on high filtration media for commercial buildings, homes, and schools as a potential stop gap to help protect building occupants. For residential settings, the California Energy Commission (CEC) recently mandated that MERV 13 filter media be used in new construction, per Title 24 Standards. Last year, the state of New York ordered shopping mall owners to upgrade to MERV 13 filters as a condition of reopening in the summer.

HEPA filters

The prevalence of HEPA (High-Efficiency Particulate Air) media, which is media with higher particulate efficiency than the MERV designation, is also increasing rapidly in medical applications, commercial settings, and even schools. HEPA filters are designed to capture 99.97% of particles that are 0.3 microns or larger. If we see a significant shift toward HEPA media, it is worth noting that some HVAC systems will need to be upgraded to augment air flow, in order to balance increased system pressure requirements against more efficient filtration media.

Associated challenges

With this increased emphasis on filtration comes higher performance requirements and greater demands on filter media, including more frequent filter changes. It is also likely that many HVAC system designers will need to begin considering the impact of high performing filtration media on HVAC system airflow and energy requirements to ensure that system performance does not suffer as a result of improved filtration.

Filtration media solutions

Johns Manville provides a wide range of product coverings for the production of pocket and pleated filters for HVAC systems in hospitals, the food and beverage industry, the pharmaceutical industry and various industrial applications. Our HVAC glass microfiber media effectively filters fine dust, bacteria, paint pigments and tobacco smoke by combining low pressure drop with a high dust holding capacity.

For more information on JM’s air filtration media, visit the HVAC filtration page of our Engineered Products division.

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

Engineered ProductsIndustry Insights, Sustainable Innovations, and Market Adaptability: A Comprehensive Overview from the Global Gypsum & Insulation Conference 2023

-

CommunityInternational Glass Artist Blends Illusion and Reality Using Johns Manville Materials

-

Engineered ProductsJM Reinforces Global Manufacturing Footprint as Tom Kendrick Returns as Global Fiberglass Commercial Director

-

Engineered Products