JM recently released CladStone™ Water and Fire Block Mineral Wool Insulation in two new densities, 8.0 pcf and 11.0 pcf. This rounds out the product line, which now offers four different densities, however, one of the main questions many people have is which density to use for specific applications.

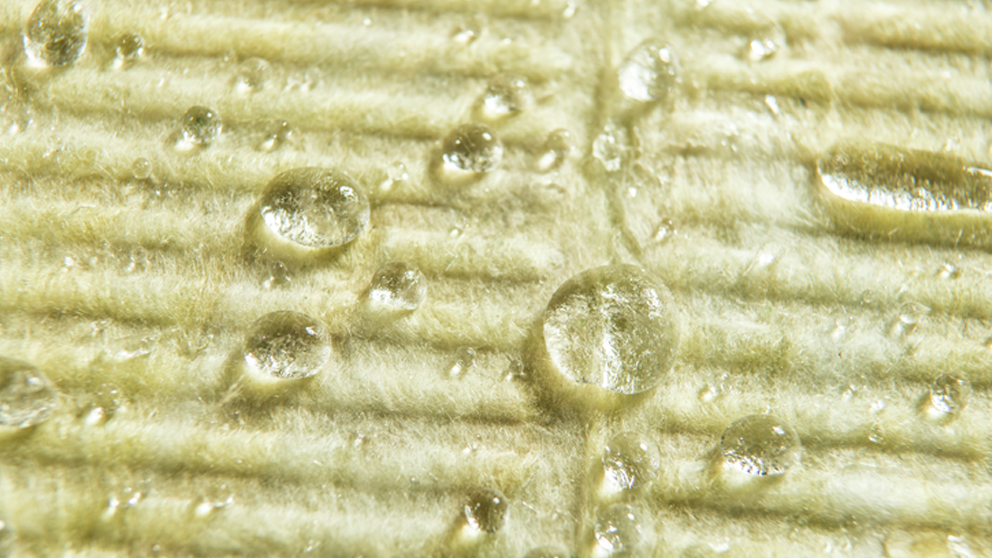

Each density of JM’s CladStone™ Water and Fire Block mineral wool has a variety of benefits and characteristics that specifiers can capitalize on for the unique demands of their applications. As with the entire JM mineral wool product line, CladStone™ is noncombustible and water-repellent, making it ideal for most rainscreen and continuous insulation applications.

Below, we’ve outlined exactly what those benefits are and some of the distinct differences in each of the CladStone™ densities and the types of applications where it would be most beneficial to use each one.

CladStone™ 45:

CladStone™ 45 is our lowest density (4.5 pcf) and most popular mineral wool board product. It offers an R-value of R-4.3 per inch, and it can be ordered in thicknesses up to 7 inches, which is the thickest CladStone™ product JM offers. When compared to the heavier density products, CladStone™ 45 is more flexible, lighter weight, and less expensive. It is also the most popular density to be specified. The light weight and flexibility make CladStone™ 45 ideal for applications where it will be friction-fit into the cladding attachment system. Lower density boards are designed for cladding attachment systems where the insulation is not subject to high compressive loads. The lightweight flexibility of CladStone™ 45 makes it ideal for these friction-fit type of applications.

CladStone™ 60:

CladStone™ 60 is one of two mid-density boards that we offer at JM. It has a density of 6.0 pcf and an R-value of R-4.3 per inch. As the density on our CladStone™ mineral wool boards increases, the available thicknesses decrease. As a result, CladStone™ 60 comes in a maximum thickness of 6 inches. Much like CladStone™ 45, CladStone™ 60 is also best used in applications where it can be friction-fit into the cladding attachment system. While it is more robust than CladStone™ 45, it still lacks the compressive strength that we find in CladStone™ 80 and 110. As a middle ground between the products, it can be pinned when necessary, and is ideal for applications where a more robust and slightly less flexible insulation is needed than CladStone™ 45.

CladStone™ 80 & CladStone™ 110

CladStone™ 80 and CladStone™ 110 are our new CladStone™ releases, with densities of 8.0 pcf and 11.0 pcf, respectively. Both densities offer an R-value of R-4.2 per inch and come in a maximum thickness of 3 inches. The boards can be double-layered if a higher R-value is necessary for the application. These higher density boards are better suited for applications where the cladding attachment system is installed with mechanical fasteners (screws). The fasteners can go over the insulation or through the insulation into the structure of the building. This creates a higher compressive load that would otherwise compress a lower density insulation. CladStone 80 and 110 can bear the compressive loads to be sandwiched between the cladding supports and the sheathing. This creates a true continuous insulation system, without thermal bridges at the girts that could allow heat transfer.

The variety of densities of CladStone™ Water and Fire Block Mineral Wool boards can be tremendously helpful to system specifiers looking for a robust and adaptable product. While CladStone™ 45 is the most popular density, the other three densities also play an important role in continuous insulation applications. If you are looking for more information on CladStone™ mineral wool, please visit our website or review our product selector guide or our installation guide.