When it comes to insulating large-diameter tanks and vessels, insulation requirements and installation practices are unique. The sheer size of these large-diameter structures introduces new challenges that simply aren’t as common with typical pipe insulation applications. To ensure that your tanks and vessels are set up for success, we’ve outlined six key considerations you need to keep in mind when designing, specifying, and installing insulation systems for large-diameter tanks and vessels.

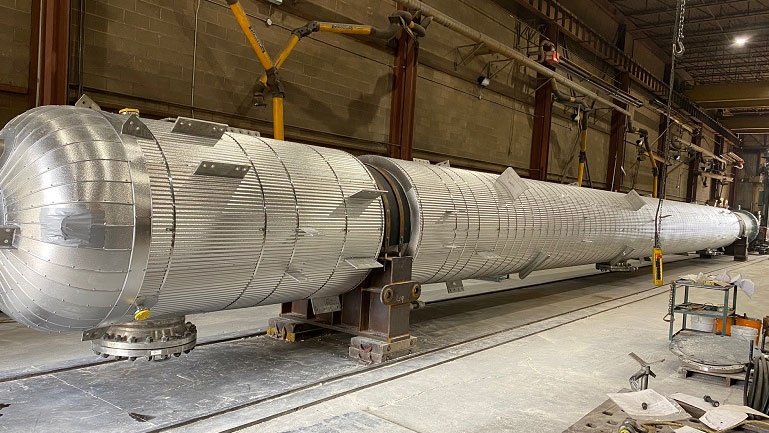

1. The vast majority of the insulation installation will be done from scaffolding: In industrial applications, these large-diameter tanks and vessels can be anywhere from 10-feet high to more than 100-feet high. This means that when the insulation is installed, the vast majority of it will be done from a scaffold or man-lift. This can limit space for maneuverability and make it difficult if not impossible to fabricate pieces on the fly. To accommodate the scaffolding, material will typically be fabricated on the ground and then put into place from the scaffold. This added step makes the process much more labor-intensive than a standard pipe insulation installation. For this reason, flexible, lightweight, blanet type insulations like MinWool-1200® Pipe and Tank Wrap mineral wool, Micro-Flex® fiberglass large-diameter pipe and tank wrap, and InsulThin® HT microporous blanket, tend to be popular choices for vessels of this size because of their size, weight, and maneuverability. Additionally, each of these insulations can be pinned to the vessel rather than held on by banding wire, making them easier to install.

If it is not possible to use weld pins to install the insulation, metal bands are used. The use of bands also allows for the use of other types of more rigid insulations like Thermo-1200® calcium silicate and Sproule WR-1200® expanded perlite.

2. Insulation support rings are critical: Tanks need to be insulated on all sides, and on vertical tanks and vessels, that means the insulation will be stacked on top of itself (as shown in the image below from the Midwest Insulation Contractors AssociationMICA manual1). If insulation support rings are not welded to the tank, the insulation on a vertical piece of equipment will start to sag or slip downward. Insulation support rings are typically specified by the engineer and can be placed every 10, 12, or 16 feet. These support rings are critical to ensure the entire system remains insulated as designed.

It’s important to note that while insulation support rings are necessary, they also create areas that are highly prone to corrosion under insulation (CUI). Frequently, water can seep beneath the jacket and pool on top of the support ring beneath the insulation. The longer the water sits against the metal of the tank or vessel, the more likely it is that corrosion will occur. To avoid this, designers usually specify support rings to be installed at a slight downward angle or with slits to allow for drainage. A robust maintenance plan will account for this potential weakness in CUI defense, and it will ensure that insulation support rings are an area of focus for regular inspection and maintenance.

3. There will be many cutouts: Tanks and vessels frequently require a lot of cutouts to accommodate manways, nozzles, anchors, etc. At each of these locations, the insulation will need to be carefully cut to allow for the various appendages. More importantly, however, the area will also need to be carefully weatherproofed. Every single cutout is a potential Achilles heel for water penetration, and installers need to take the time to properly seal the cutout with a high-temperature caulk that can withstand the demands of the application.

Keep in mind that because large tanks and vessels require scaffolding to insulate and inspect, they are more costly to inspect than pipes that are lower to the ground and easier to access. Because of this, large-diameter tanks and vessels may end up on longer inspection schedules. With this in mind, careful weather sealing should be a top priority for all cutouts and joints to ensure the system is built for long-term durability and limited CUI risk.

4. Thermal expansion and contraction are significant and must be accounted for in the design: The sheer size of large tanks and vessels, when compared to standard pipes, creates an environment where expansion and contraction must be considered during the design phase. This means that the system should be designed to accommodate the expansion/contraction, using tools like expansion springs that will allow the entire insulation and jacketing system to flex with the expansion or contraction of the tank or vessel beneath it. Additionally, all the insulation should be double-layered and the layers should be staggered so there is never a direct pathway from the surface of the tank to the metal jacketing as the expansion or contraction occurs.

5. People walk on the tops of tanks: If the top of the tank is going to be insulated, it should be insulated with a material that has high compressive strength, like Thermo-1200® calcium silicate or Sproule WR-1200® expanded perlite. Both of these materials have excellent compressive strength (>100 psi, and 80 psi respectively) that stands up against the rigors of applications where plant personnel walk on the insulated systems. If a softer insulation is used, like mineral wool, it could buckle under the weight of the plant personnel, creating gaps in the jacketing and increasing the likelihood that water will enter the system and contribute to CUI.

6. Pre-engineered paneled systems are an easy solution for some systems: There are some companies that fabricate and insulate sheet metal jacketing in offsite fabrication shops with fiberglass insulations like 1000 Series Spin-Glas® or Precipitator Spin-Glas®. These are called pre-engineered paneled systems. While not right for every application, for some applications, this solution can be a faster and easier alternative to applying the insulation and jacketing independently.

As with most industrial applications, large-diameter tanks and vessels require more detailed consideration than simply insulating for thermal or acoustical performance. To appropriately protect and insulate these types of applications, installers need to consider everything from thermal performance to CUI to whether or not plant employees are likely to be walking on the insulation. By keeping these details in mind, and scheduling a rigorous inspection and maintenance plan, you can keep these large structures in excellent operating condition for years to come.