Fire resistance is a critical factor in the safety and reliability of materials like thermoplastics and gypsum boards, which are essential in industries including automotive, construction, and more. Their ability to withstand fire can mean the difference between containment and catastrophe. At Johns Manville (JM) we understand this critical need and have developed advanced testing facilities to ensure our glass fibers significantly enhance the fire resistance of these applications. In this blog post, we delve into some of our testing capabilities at our site in Trnava, Slovakia and highlight the essential role our glass fibers play in improving fire safety.

Thermoplastic Flammability Test

The thermoplastic flammability test at our Trnava plant is based on the UL 94 standard, a globally recognized benchmark for flammability testing of plastic materials. This test is essential for assessing how our glass fibers influence the fire resistance of thermoplastics used by our customers.

František Sabo, Global I&C Leader, explains: " The additives our customers use in their processes enable good fire resistance in thermoplastics, but also our glass fibers play a significant role. The sizing on our fibers can either accelerate or retard the spread of fire, making our testing capabilities crucial for both our R&D and customer assurance."

Test Procedure

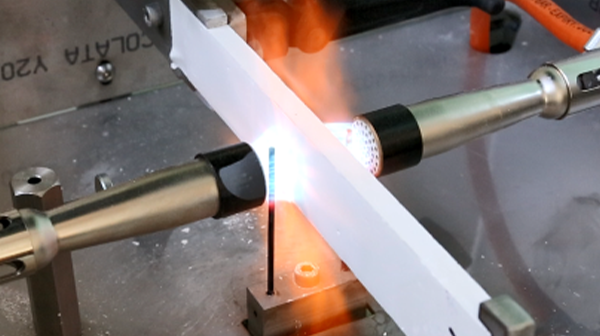

The flammability test involves exposing a pre-prepared plastic specimen to a flame under controlled conditions. The test is conducted in two formats: horizontal and vertical.

- Horizontal Test: The specimen is mounted horizontally, and a flame is applied for 30 seconds. We observe whether the specimen ignites and measure the time it takes for the flame to travel between predefined marks. The burn rate is calculated in millimeters per minute.

- Vertical Test: The specimen is mounted vertically, and the flame is applied from the bottom for 10 seconds. After the flame is removed, we measure the afterflame and afterglow time, and whether burning particles drip off the specimen. Depending on the observations of both tests, the materials get classified into categories indicating their slow burning, flame retardant or self-extinguishing properties and any potential burning drips.

Benefits and Importance

Zuzana Krajcovicova, Senior Product Development Engineer, adds: "We provide these testing services to our customers, allowing them to understand how our glass fibers impact the fire resistance of their products. This not only helps in ensuring safety but also aids in the development of more fire-resistant materials."

Gypsum Cohesion Test

Fiberglass is integral to the performance of gypsum boards, providing both impact and fire resistance.

Zuzana explains: “The plasterboard contains gypsum crystals that hold water, which is released during a fire. This release leads to shrinkage and cracks in the plasterboard. Glass fiber in the plasterboard improves stability and prolongs the time until the board is destroyed. The core cohesion test helps demonstrate how our fiberglass extends the time until the gypsum board breaks down under fire conditions.”

Test Procedure

The core cohesion test for gypsum boards, based on the EN 520 standard, is a practical alternative to other more complex and more expensive tests and provides valuable insights into the fire resistance of gypsum boards very promptly. It involves placing a gypsum board specimen between two burners and measuring the time until it collapses.

The specimen is fixed on one side, while a load is applied on the other side. The burners heat the specimen, and we measure the time until it shows signs of failure such as cracking or breaking.

František notes: "Our core cohesion test is invaluable for understanding how different types of glass fibers affect the fire resistance of gypsum boards. We can compare specimens without fiberglass with JM’s DuraCore® chopped fiberglass and DuraChop® and MultiStar® assembled rovings with different sizing formulations to see which provides the best performance."

Test Comparisons and Results

Our internal tests have shown that DuraCore® chopped fiberglass and DuraChop® assembled rovings significantly enhance the fire resistance of gypsum boards compared to e.g. MultiStar® assembled rovings not specifically designed for this application.

Zuzana concludes: "These tests highlight the superiority of our DuraCore® and DuraChop® fibers in fire resistance. While customers typically perform their own tests, our findings provide a solid foundation for the development of superior fiberglass products our customers can use in their gypsum board formulations."

Conclusion

The advanced testing capabilities at our Trnava, Slovakia plant but also at our Johns Manville Technical Center in Littleton, Colorado, USA underscore our commitment to delivering high-performance glass fibers that enhance the fire resistance of thermoplastics and gypsum boards. By continually refining our products through rigorous testing, we ensure that our customers receive materials that meet the highest standards of safety and quality.

Our tests not only demonstrate the effectiveness of our glass fibers but also provide valuable data that helps our customers optimize their products for better fire resistance.

-

Engineered Products

-

Engineered Products

-

Engineered Products

-

Engineered ProductsHow to Solve Industrial Filtration Challenges with Evalith® Micro Fiberglass Filter Tube Media

-

Engineered Products