As summer temperatures soar, the risk of heat-related illnesses in industrial settings becomes a significant concern. High heat can lead to dangerous conditions such as heat exhaustion, heat stroke, and other heat stress disorders, posing a serious threat to the safety of employees. Effective heat stress management is crucial for manufacturing facilities, especially those located in regions with extreme temperatures.

We talked to some real experts about this topic. Willie Smith, Production Superintendent, and Danny McCree, EHS Manager, work at the southernmost JM Engineered Products production site in Richland, Mississippi. The plant is situated in a humid subtropical climate and has implemented comprehensive measures to mitigate heat stress risks, ensuring that its workforce remains healthy even in the hottest months.

JM: Willie, Danny – thanks for shedding a light on the measures we're implementing at our Richland facility to ensure the safety and well-being of our employees. Can you start by telling us a bit about the unique challenges your team faces, especially during the summer months?

Danny: Mississippi is known for its hot and humid climate. Summers here are long and hot, with temperatures and humidity that can be stressful for the body. The heat index often climbs above 90°F, putting us in the "Extreme Caution" category as defined by OSHA's Heat Stress Initiative. This makes it crucial for us to adopt comprehensive measures to prevent heat-related illnesses among our workforces. In addition, our production lines generate a significant amount of heat. These combined factors present unique challenges to our plant.

JM: What kind of materials do you produce in Richland?

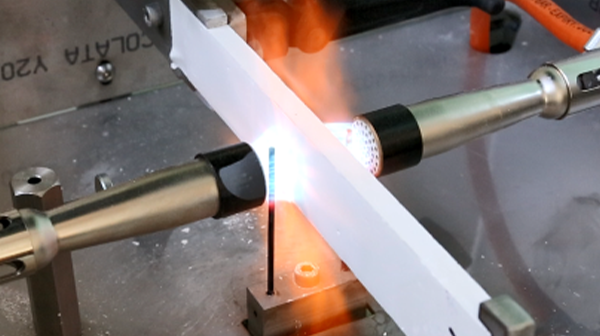

Willie: We make PP meltblown nonwovens, mainly used in air and liquid filtration applications. A meltblown filter media is created from molten polymer resin. A hot air stream stretches the fibers to a final fiber size in the micrometer range and after that the textile gets calendered and wound onto a core. The fabric is available in various designs, thicknesses and widths.

JM: Could you elaborate on the OSHA Heat Stress Initiative and how it influences your safety protocols?

Danny: Absolutely. In 2021, OSHA launched an enforcement initiative aimed at preventing heat-related illnesses. This initiative prioritizes inspections on days when the heat index exceeds 80°F. The heat index, which combines heat and humidity, helps us categorize the risk levels: Caution, Extreme Caution, Danger, and Extreme Danger. Based on these levels, we have implemented specific controls and procedures to ensure our workers' safety.

JM: What are some of the specific procedures and controls you’ve put in place at the Richland plant?

Willie: We have several key measures. Firstly, acclimatization procedures for new workers are critical. They start with 20% exposure on the first day, increasing by no more than 20% each subsequent day. We also implement work/rest schedules, particularly on days with a high heat index. Additionally, we use environmental monitors to measure local temperature and humidity, considering both outdoor and process-generated heat.

JM: How do you monitor the health and safety of your team?

Willie: We utilize wearable biometric monitoring devices that measure core body temperature, heart rate, and the worker's microclimate. This real-time data helps employees identify potential heat stress before it becomes a serious issue. Furthermore, we have ice chests with hydration and electrolyte replacements, and we provide cooling bandanas, neck gaiters, and cooling vests to help manage body temperature.

JM: It sounds like you have a comprehensive approach. What kind of training do you provide to your employees?

Danny: Training is a cornerstone of our strategy. We educate both employees and supervisors on the signs and symptoms of heat stress and the controls we have in place. This includes recognizing early symptoms like excessive sweating, fatigue, and dizziness, and knowing the appropriate actions to take.

JM: With such high temperatures, humidity, and process heat, can you tell us more about the equipment you use in the operations area to maintain a safe environment?

Willie: We have invested in portable evaporative coolers, large fans, cooling chairs, and cooling tents with portable AC units.

JM: Finally, how do you ensure continuous improvement in your heat stress prevention measures?

Danny: We continuously review and refine our strategies based on research, feedback from employees, and technological advancements. Regular audits and inspections help us identify areas for improvement. Moreover, we stay updated with OSHA guidelines and industry best practices to ensure we’re always ahead of the curve.

JM: Thank you, Willie and Danny, for sharing your insights. It’s clear that the Richland plant is taking proactive and comprehensive steps to protect our employees from heat stress. Stay cool and stay safe!

-

Engineered ProductsJohns Manville MultiStar ® 272 - Your Key to Achieving Class A Surface Quality in Automotive Applications

-

Engineered Products

-

Engineered Products

-

Engineered Products