Resources

Products

Fiberglass Insulation

Johns Manville Formaldehyde-free™ fiberglass insulation provides thermal and accoustical control for both vertical and horizontal applications. Fiberglass insulation is available in a wide range of thermal resistance R-values and is available unfaced or with a variety of facings, including kraft or foil.

Fiberglass

Cavity-SHIELD Fiberglass

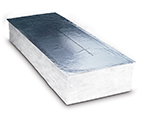

JM Formaldehyde-free™ Cavity-SHIELD™ fiberglass batts are made of long, resilient glass fibers bonded with a thermosetting resin. A wide range of thicknesses are available to provide NFPA 13 compliant passive fire protection in lieu of sprinklers for horizontal floor-ceiling cavities. Cavity-SHIELD fiberglass batts are available unfaced.

Advantages

Noncombustible: ASTM E 136, NFPA 13 Section 9.2.1 compliant

Simple Installation: no special equipment required

Cost-effective: economical alternative to blow-in insulation

Formaldehyde-free: will not off-gas formaldehyde in the indoor environment

Sound Control: reduces transmission of sound through floor or ceiling assemblies

Fire Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less (ASTM E84), Class A1

Durable Inorganic Glass: will not rot, mildew or deteriorate and is noncorrosive to pipes, wiring and sheet metal ducts

| ASTM Standards | ASTM C665 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Data Sheet

Literature

Certifications and Specifications

Cavity-SHIELD Fiberglass

Fiberglass Batts EPD

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation

Warranties

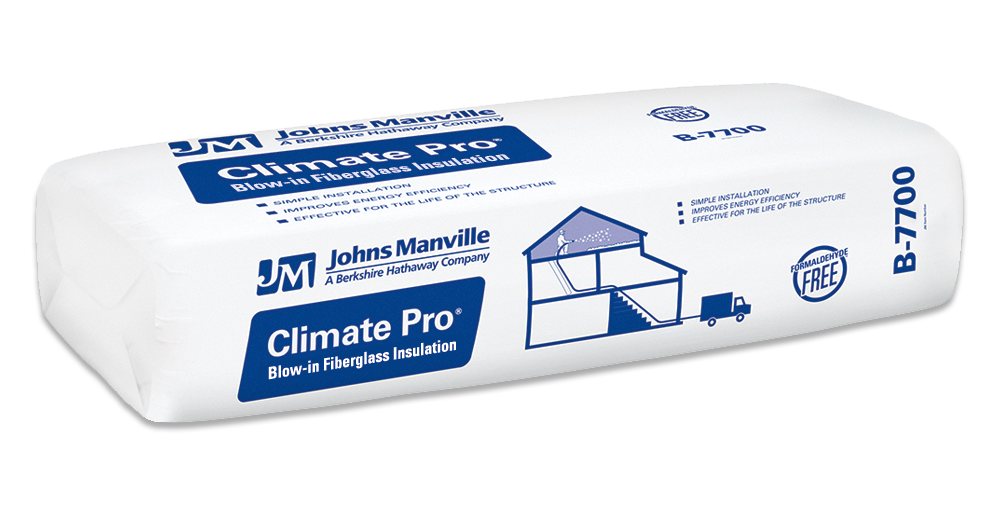

Climate Pro Blow-In

Johns Manville Climate Pro® Formaldehyde-free™ blow-in, loose-fill fiberglass insulation offers thermal and sound control along with fire resistance. One bag of Climate Pro provides 77.1 square feet of R-30 coverage. Engineered for professional use with high-volume blowing machines, it's ideal for attics, nonconforming spaces and hard-to-reach areas making the job faster and easier.

Advantages

Easy Installation: Insulates attics or spaces of all shapes and sizes without cutting or fitting.

Complete Coverage: Effective in tight spaces, areas with large amounts of cross-bridging, or small gaps and voids.

Thermally Efficient: Effective resistance to heat transfer. No settling; no loss of R-value following installation.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 5 or less and Smoke Developed of 5 or less.

Resilient Inorganic Glass Fibers: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C764 | Type I |

| Flame Spread | ASTM E84 | ≤ 5 |

| Smoke Development | ASTM E84 | ≤ 5 |

| Critical Radiant Flux | ASTM E970 | > 0.12 W/cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C764 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustible Characteristics | ASTM E136 | Pass |

| VOC Emissions | ES Section 01350 | Pass |

Data Sheet

JM Climate Pro B7700 Data Sheet

Installation Instructions

JM Climate Pro B7700 Install Instructions

Climate Pro B-7700 Install Instructions Spanish

Climate Pro PresSure Gauge User Guide

SDS

Climate Pro Blow-In SDS

Climate Pro Blow-In SDS (ES)

Literature

Product Selector Guide

Blowing Wool Coverage Check and Easy Fix Checklist

Blowing Wool Coverage Check and Easy Fix Checklist (ES)

Certification and Specifications

Fiberglass

Loose Fill Fiberglass EPD

Climate Pro GREENGUARD Gold Certification

Climate Pro GREENGUARD Certification

Climate Pro Formalde-hyde Free™ Claim Validation

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation

Best Practices for Installing JM Climate Pro®

ComfortTherm

Johns Manville ComfortTherm® poly-encapsulated thermal and acoustical insulation offers R-Values up to R-30 and is available in precut batts to fit standard wall cavities or rolls for custom installation in any size of wall cavity. ComfortTherm® insulation is wrapped in plastic for dust-free, itch-free installation, and can be used in a wide variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Can be left exposed where building codes permit. Flame Spread of 25 or less and and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type II, Class A, Category 1 or 2 [Standard ComfortTherm is Category 1 (vapor retarder). ComfortTherm for hot, humid climates is Category 2 (non-vapor retarder).] |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance |

ASTM E96 | 0.5 Perms (29 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Data Sheet

SDS

ComfortTherm SDS

ComfortTherm SDS (ES)

Certifications and Specifications

Fiberglass

Fiberglass Batts EDP

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

Literature

Warranties

FSK-25 Batts

Johns Manville Formaldehyde-free™ FSK-25 thermal and acoustical fiberglass insulation is available in R-Values up to R-30, and is offered in precut batts to fit standard wall cavities. FSK-25 faced batts combine fire resistance with excellent vapor resistance, and can be used in a wide variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit. FSK-25 batts are designed with a foil facer that can be left exposed where codes permit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less. Can be left exposed where building codes permit.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type III, Class A, Category I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance Facing | ASTM E96 | 0.05 Perms (3 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Insul-SHIELD Black

Johns Manville Insul-SHIELD® Black is a series of flexible, semi-rigid or rigid thermal and acoustical fiberglass insulating boards for custom curtainwall applications. Insul-SHIELD is fire-resistant and noncombustible, available faced and unfaced, and designed to be used in new and retrofit construction, metal panel buildings and in general construction. With its black core, Insul-SHIELD Black is ideal for applications including theater screens, parking structures, mechanical rooms and sports arenas.

Advantages

Acoustically Efficient: Reduces transmission of sound through roofs, ceilings, floors and walls.Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Noncombustible: Unfaced I/S 150, I/S 300 and I/S 600 are non combustible.

Moisture-Resistant: Vapor-retarder facings resist water vapor transmission.

Noncorrosive: Prevents acceleration of corrosion to pipes, wiring and metal studs.

Durable: Will not rot, mildew or otherwise deteriorate, preventing slumping and uninsulated voids.

Easy to Handle: Lightweight; maintains its physical integrity during handling.

| ASTM Standards | ASTM C612 | Type IA or Type IB (IS150, IS300, IS600) |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Max Use Temp | ASTM C411 | 350ºF |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM C665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | IS150, IS300, IS600: Pass; Black IS300, IS600: Pass |

| 10% Linear Shrinkage | ASTM C356 | None |

Literature

Product Selector Guide

Insul-SHIELD Black FAQ

Insul-SHIELD Black Sales Aid

Specifications

Kraft Faced Fiberglass

Johns Manville Formaldehyde-free™ Kraft-faced thermal and acoustical insulation offers R-Values up to R-49, and is offered in precut batts to fit standard wall cavities or rolls for custom installation in any size cavity. Kraft-faced insulation is ideal for moisture control in exterior walls, reduces sound transmission through walls, ceilings and floors, and can be used in a variety of wood-framed, engineered wood and steel frame construction applications, including new construction and retrofit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-49.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type II, Class C, Category 1 |

| Water Vapor Permeance Facing | ASTM E96 | 1.0 Perms (57 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Data Sheet

Kraft Faced Fiberglass Data Sheet

SDS

Kraft Faced Fiberglass SDS

Kraft Faced Fiberglass SDS (ES)

Certifications and Specifications

Fiberglass

Fiberglass Batts EDP

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

Literature

Warranties

Panel Deck FSK-25

Johns Manville Panel Deck FSK-25 Formaldehyde-free™ thermal and acoustical insulation is available in R-Values up to R-30 and combines fire resistance with an excellent vapor retarder. Panel Deck FSK-25 insulation is offered in precut batts with extra-wide tabs for modular roof deck applications and other speciality commercial applications. This product is designed with a foil facer that can be left exposed where codes permit.

Note: Color of product may differ based on the manufacturing location.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-30.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less. Can be left exposed where building codes permit.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type III, Class A, Category I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Permeance Facing | ASTM E96 | 0.05 Perms (3 ng/Pa-s-m2) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

Spider Plus Blow-In

Johns Manville Spider® Plus Formaldehyde-free™ blow-in fiberglass insulation uses interlocking fiber technology to fill all gaps and voids quickly with no adhesive or netting for a faster installation. Spider Plus provides complete coverage, with no shrinking or settling, resulting in superior thermal performance and sound control. Designed for use in wood- and metal-frame construction, engineered- wood construction and manufactured homes.

Advantages

Fast Drying: Dries immediately once installed.

Complete Coverage: Effective in tight spaces, areas with large amounts of cross-bridging or small gaps and voids.

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-25 in a 6'' cavity.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

| ASTM Standards | ASTM C764 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Critical Radiant Flux | ASTM E970 | > 0.12 W/cm2 (0.11 Btu/ft2s) |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Data Sheet

Spider Plus Blow-In Data Sheet

SDS

Spider Plus Blow-In SDS

Spider Plus Blow-In SDS (ES)

Sell Sheet

Spider Plus Blow-In Sell Sheet

Certifications and Specifications

Spider-Plus Blow-In Fiberglass

Loose Fill Fiberglass EPD

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation

Installation Instructions

Spider Plus Consolidated Install Instructions

Spider Plus Consolidated Install Instructions (ES)

Spider Plus Full Install Instructions

Spider Plus Full Install Instructions (ES)

Coverage Card

Spider PLUS Closed Cavities Coverage Card

Literature

Case Study

Unfaced Fiberglass

Johns Manville Formaldehyde-free™ Unfaced thermal and acoustical insulation offers R-Values of up to R-49, and is offered in precut batts to fit standard wall cavities or rolls for custom installation in any size cavity. Unfaced insulation reduces sound transmission through walls, ceilings and floors, and can be used in a variety of wood frame, engineered wood and steel frame construction applications, including new construction and retrofit.

Advantages

Thermally Efficient: Effective resistance to heat transfer, with R-values up to R-49.

Formaldehyde-free: Will not off-gas formaldehyde in the indoor environment.

Sound Control: Reduces sound transmission through exterior and interior walls, floor and ceiling assemblies.

Fire-Resistant: Flame Spread of 25 or less and Smoke Developed of 50 or less.

Resilient Inorganic Glass: No rotting, mildew or deterioration. Also noncorrosive to pipes, wiring and metal studs.

Superior Performance: Stable bonded glass fibers will not slump within the wall cavity, settle or break down during normal applications.

| ASTM Standards | ASTM C665 | Type I |

| Flame Spread | ASTM E84 | ≤ 25 |

| Smoke Development | ASTM E84 | ≤ 50 |

| Water Vapor Sorption | ASTM C1104 | 5% or less by weight |

| Odor Emission | ASTM C1304 | Pass |

| Corrosiveness | ASTM 665 | Pass |

| Fungi Resistance | ASTM C1388 | Pass |

| Combustion Characteristics | ASTM E136 | Pass |

Installation Instructions

Fiberglass Installation Instructions

Fiberglass Installation Instructions (ES)

Literature

STC Rating Documents

Acoustical Assemblies STC Rating Reference Guide

Certifications and Specifications

Fiberglass

Fiberglass Batts EPD

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Certification

Formaldehyde-free™ Fiberglass Insulation GREENGUARD Gold Certification

Formaldehyde-free™ Fiberglass Insulation Claim Validation